Chemical

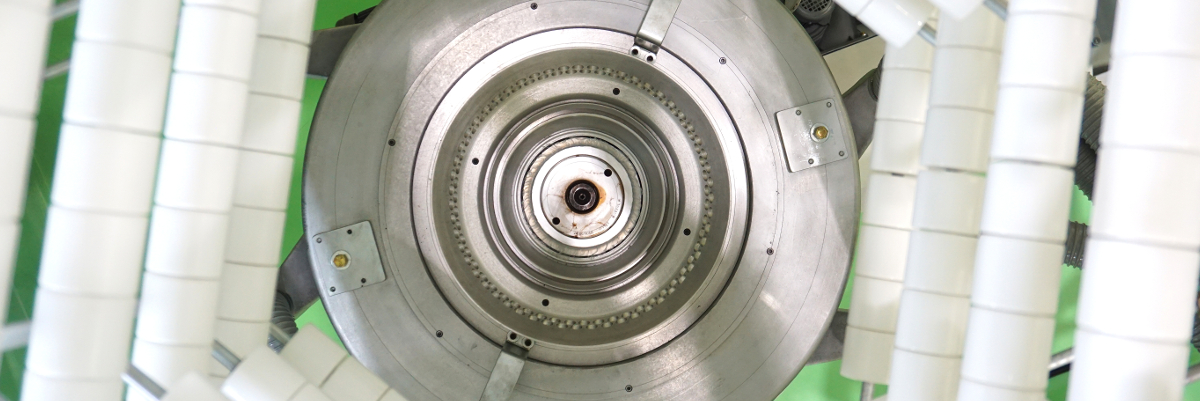

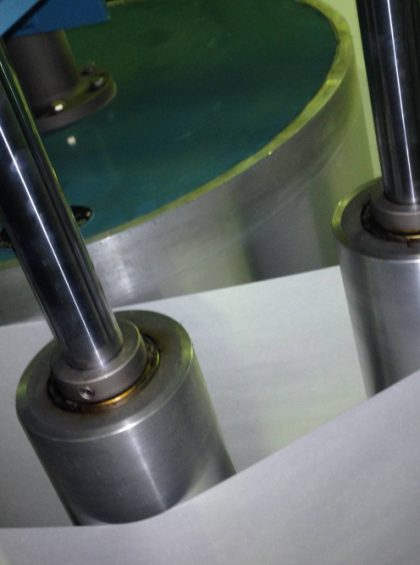

Machine alignment on various machines like blown film extruders, laminating and coating machines are critical due to the nature of the product having a very narrow tolerance. We also offer mechanical maintenance in this area due to the many years of working closely with in this area of production/engineering, working in various aspects from carbon fibre to HDPE.

Make An EnquiryWhy Optimech?

Optimech has been providing specialist alignment and mechanical services to the engineering and industrial sectors since our establishment in 1998.

Over the years we have performed thousands of alignment services, machine instillations, and general engineering services both nationally and internationally.

We can respond quickly to jobs of any size or complexity, anywhere our services are needed – 24 hours a day, seven days a week.

Optimech Benefits

- Over 20 Years Experience

- Industrial engineering principles

- Cost Effective and professional

- Specialist alignment and mechanical services

- 24 Hours a day, seven days a week

-

Machine Alignment

-

Corrugator Alignment

-

Laser Shaft Alignment

-

Machine Installations

-

Mechanical Maintenance